Our grab sampling assemblies come in various configurations and are locally built, supported, and reliable. They are designed to safely collect representative samples of liquid or gas from your process lines. We offer options for closed-loop sampling into pressure-rated sample cylinders or collecting process fluid into glass laboratory bottles for analysis. Our sampling panel options are easy to use, maintain, and can be ordered as a single part number.

Created by Swagelok Engineers, Tailored for Your Needs.

Swagelok grab sampling systems are crafted to safeguard both your employees and your financial success, and are customized by fluid system experts to suit your requirements.Engineered For Safety

Swagelok grab sampling systems isolates the process pressure from the sample bottle and user, avoiding overfilling and overpressure situations. Our panels are also constructed with features to reduce the risk of operator mistakes, for example, a spring-return handle on the GSL sample valve that prevents unintended dispensing.

Engineered For Ease Of Use

Swagelok grab sampling systems are engineered to lower the number of steps required for sampling and are constructed for simple maintenance. A switching valve configuration on GSM and fixed-volume GSL panels enable simultaneous management of fluid routing and provides clear sequencing to the operator. Additionally, components like gauges can be separated during maintenance to reduce downtime.

Engineered For Reliable Results

Closed-loop GSM sampling panels provide samples that are stored in cylinders that maintain the same process conditions as when the sample was taken, ensuring that the sample is accurate. A GSL can use glass laboratory bottles that offer immediate observation of the visual properties of the sample. All our grab sampling panels are constructed with Swagelok tube fittings, minimizing the risk of leakage.

Customized Standard Assemblies Tailored To Suit Your Requirements.

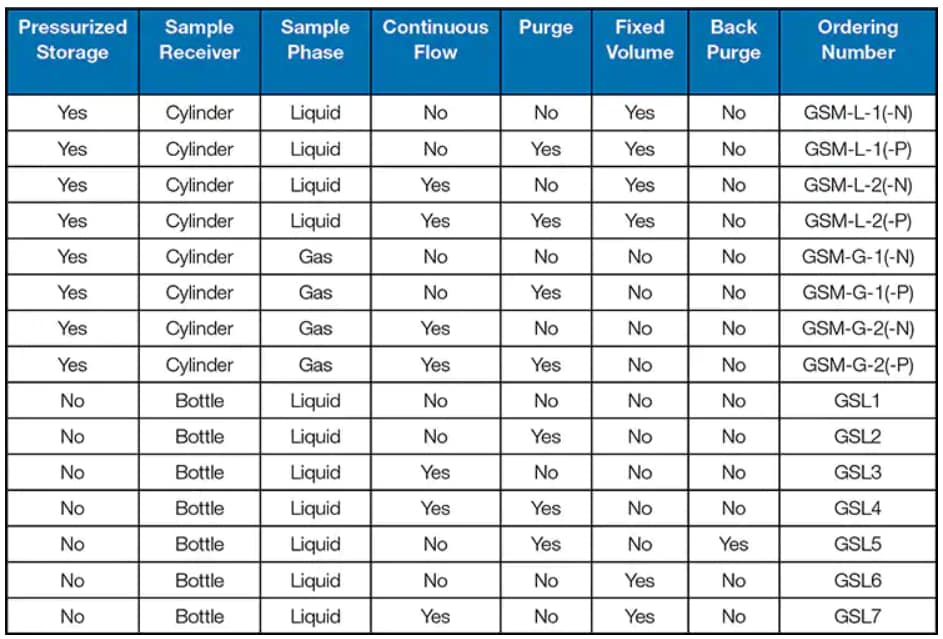

Fixed-volume versions of both GSM and GSL sampling system panel types are accessible, ensuring the segregation of process pressure from the sample bottle and user. This prevents over-filling and overpressure situations. The table below presents a condensed overview of common system criteria along with the recommended grab sampling system for each combination listed.

You can personalize Swagelok grab sampling systems according to your operational needs by incorporating various accessories such as additional instrumentation, sample coolers, automation features, exotic alloys, different mounting options, and more.

Grab Sampling Valve

Overcome the safety, maintenance, and quality challenges associated with standard bottle sampling by adding a Swagelok® grab sampling valve to your fluid system. Our leak-free design eliminates rubber O-rings by using a Swagelok® tube fitting to attach the needle assembly to the valve body.

Features of the Grab Sampling Valve

Easy Needle Replacement

Simply tighten the tube fitting nut to create two all-metal seals.

Improved Needle Design

A pencil point needle assembly pierces without coring the septum, minimizing clogged needles and leaking sample bottles.

Interchangeable Shrouds

We offer a variety of shroud options, including custom configurations to match non-standard sample bottles.

Elastomer-Free Design

By eliminating rubber O-rings, you can minimize the potential for system leaks while reducing your maintenance inventory.

Spring-Return Handle

When the Swagelok grab sampling valve is specified with a spring return handle, the valve automatically moves to the closed position when the handle is released, ensuring you collect the sample amount that you need.

Rely On A Sampling System Specialist For Trusted Results.

Learn more about the benefits of Swagelok grab sampling solutions and how the right local support by sampling system specialists can provide value to your organization. Contact us to schedule an appointment with our Grab Sampling Team today and learn more about our Grab Sampling Systems.

Ask Swagelok: Swagelok Sampling Video Series

There are many factors to consider for liquid sampling. Swagelok has put together a video series that discusses the importance of maintaining proper vapor space compression, the role of outage tubes, how vapor space is affected by sampling system design, and what you need to know to minimize the risk of cylinder rupture.

How Does The Sampling Procedure Affect The Sample Taken?

What Is Return Pressure, What Affects It, And Why Does It Matter?

What Is Vapor Space Compression And Why Can It Be Problematic?

How Does A Sample Cylinder Fill?

What Are Outage Tubes And Why Are They Important?